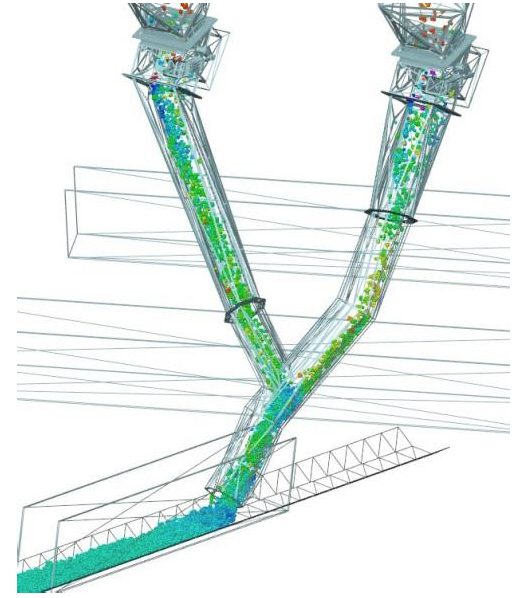

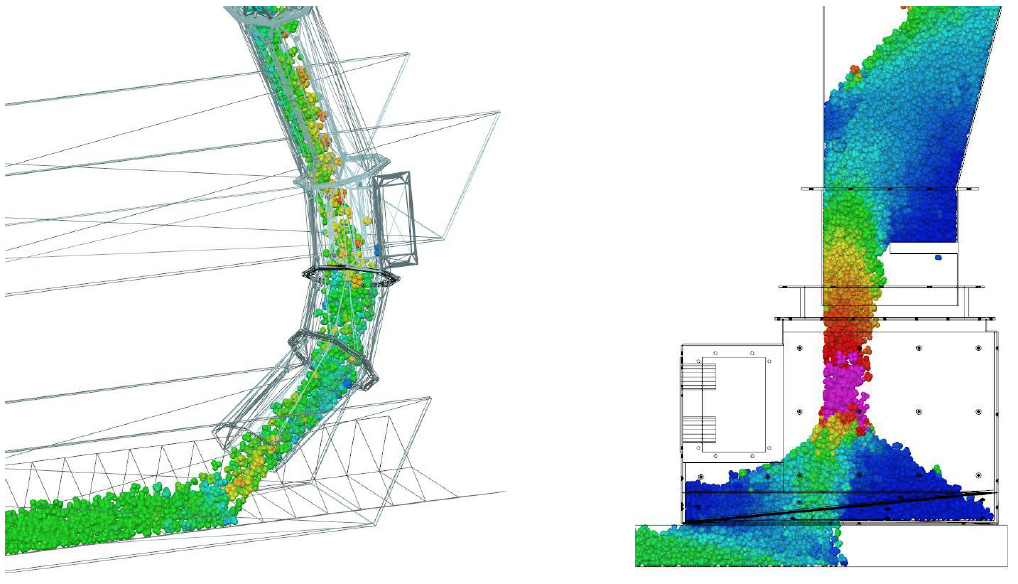

DEM Flow Analysis

DG Marshall’s Discrete Element Method (DEM) simulation package can be used to quickly and accurately model three-dimensional behavior of granular flow in a wide range of material properties including wet, sticky, and cohesive materials. DEM can provide a clear understanding of material degradation, surface wear, impact damage, energy dissipation, and other fundamental parameters. By predicting the wear on transfer chute liners, conveyor belts, and other surfaces allows the ability to qualitatively compare multiple transfer chute designs and select the optimal geometry that minimizes wear, dust generation, and material abrasion.

Benefits of DEM

• Visualize material flow

• Determine bulk material flow patterns and rates

• Analyze impact forces and wear patterns on boundary surfaces

• Regulate velocity profiles and dead zones

• Optimize chute designs and transfer points