Who We Are

DG Marshall Associates, Inc. is a family owned company specializing in the design and manufacturing of all types of conveyors and material handling systems.

With over 75 years of combined experience designing and building a wide variety of bulk material handling projects, DG Marshall has established itself as a leader and innovator in the industry. Our unique ability to design and build to our customers’ specific material handling needs separates us from the competition.

We work closely with clients to evaluate production processes and offer solutions to increase efficiency and productivity. At DG Marshall, our goal is to form lasting relationships with our customers and to provide comprehensive solutions for any material handling needs.

What We Do

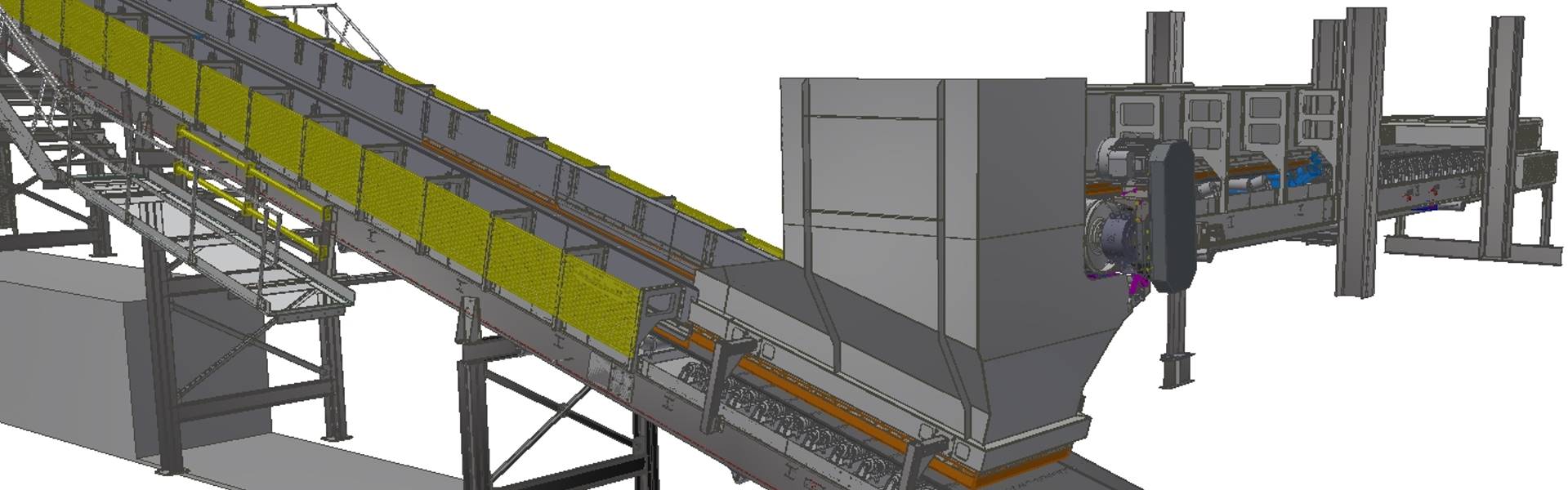

We are a full-service company, with the capability of designing and building complete, integrated systems as well as individual components.

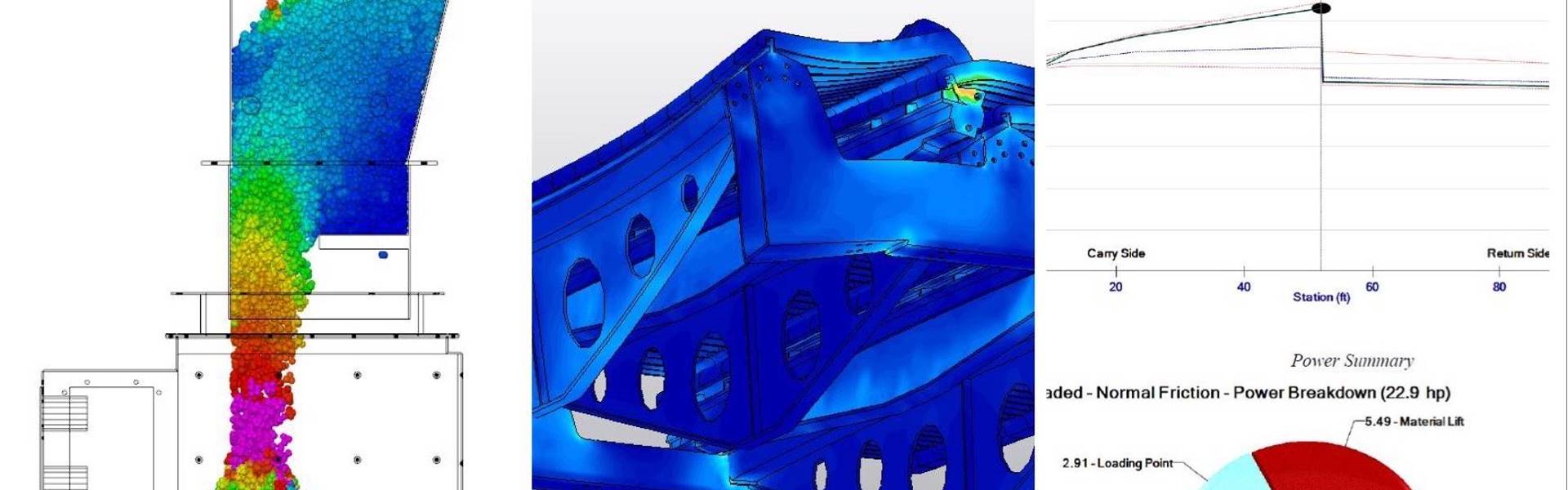

Our sales staff and project managers work together with customers to determine the best fit for their application. Onsite point cloud laser scanning of facilities and equipment is available to ensure seamless integration with existing structures and processes. From there, our engineering department uses state-of-the-art 3D modeling and FEA analysis software to design the equipment. An experienced team of fabricators and assemblers then builds the equipment to the exact specifications.

Our products include all types of conveyors (belt, drag, screw, etc.), bucket elevators, blenders, storage bins and all periphery types of products (mezzanines, walkways, galleries, ladders, etc.). We service a broad spectrum of industries from recycling and waste to energy, to bulk powders and wastewater.

Quality & Service

All of our products are constructed using only the highest quality materials and components. Each unit is built according to strict specifications and is inspected and test run prior to shipment to ensure seamless installation and integration in the field.

Our goal is to offer the best, most reliable equipment to our customers at an affordable price. We also offer a complete line of after sales spare parts and services.